Soldering systems

We offer you customised automated soldering machines for your specific application.

Our specialities include:

- Robot soldering systems with automated infeed / outfeed

- Spot soldering

- Drag soldering

- Solder bath

Everything from a single source.

We would be happy to create a concept for you based on a feasibility study.

Get in touch with us

Automatic screwing and assembly machines

- Automatic screwdrivers (Video)

- Automatic riveting machines (Video)

- Robot cells for cable processing

We automate your screwdriving process!

For fully automatic assembly, the individual parts are automatically transported to the machine and screwed to the product.Get in touch with us

Labelling and printing machines

We integrate the labelling system you require and implement the fully automatic handling of your product in the process. We also create the interface to upstream and downstream processes. Quality monitoring of the printing result is a matter of course for us.

- Labelling systems with automated infeed and outfeed

- Laser labelling

- Printing with inkjet printing

- Q-R code, 2D, 3D code printing

- Wire labelling

Get in touch with us

Test systems

- Engine test benches

- Pump test benches

- Agitator test benches

ETU offers you all the equipment you need for your tests and inspections, including the measurement of electrical power, efficiency and loss in the fields of drive technology, electromobility and high-current applications such as inverters, electric motors and converters.

ETU also calibrates complete loops for you as part of its calibration service.

From actuator and motor test benches to endurance test benches with the most sophisticated precision measurement technology on motors and drive trains.

ETU is your partner in equipping your test facility.

Get in touch with us

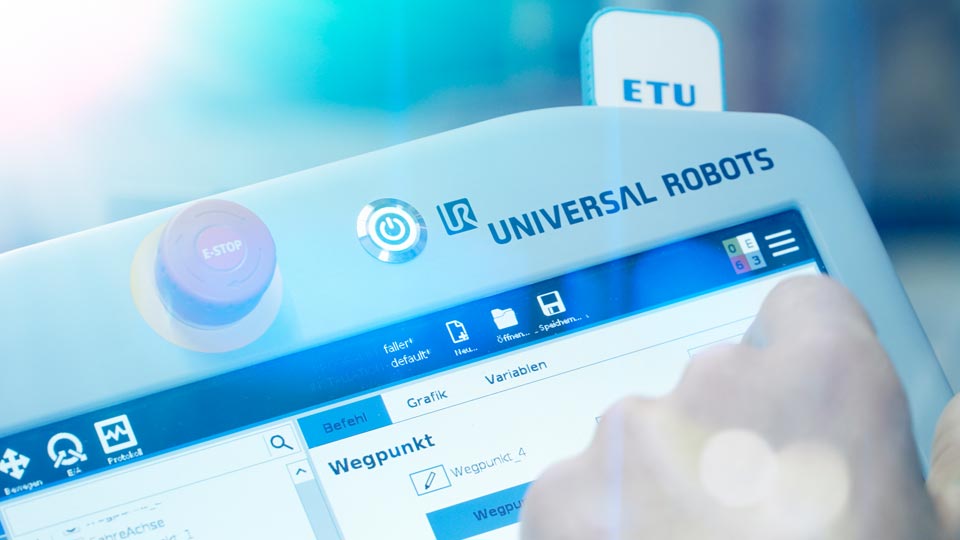

Palletising and packaging systems

Separating, removing, depositing and packing. In addition to feeding and discharging, these are the tasks that must function reliably and continuously in modern robot-based applications. The all-rounders from Universal Robots are the ideal workers in such systems. With our iPACKER, you can optimise production processes and reduce your costs. This system fulfils the highest demands on throughput, which improves efficiency and flexibility. The compact and flexible infeed and outfeed technology, supported by the UR robot, makes operation particularly easy. Intelligent buffer solutions allow one person to control several systems per shift.

- End of Line Leaflet Packaging

- Palletising and depalletising

- Pick&Place

Get in touch with us

Camera-based solutions

Whether recognising components for secure gripping of components or recognising features on components for further assembly, we integrate your vision application with various systems from manufacturers such as Cognex or Kuka,

completely harmonised with the overall system.

If you have a testing task or need to verify a QR code or a print, we will create the right concept for you in a feasibility study.

- Printing of flexible parts with inkjet printing

- Q-R code, 2D, 3D code or labelling

- Vision inspection system

- Length measuring systems

- Part recognition and robot integration

Get in touch with us

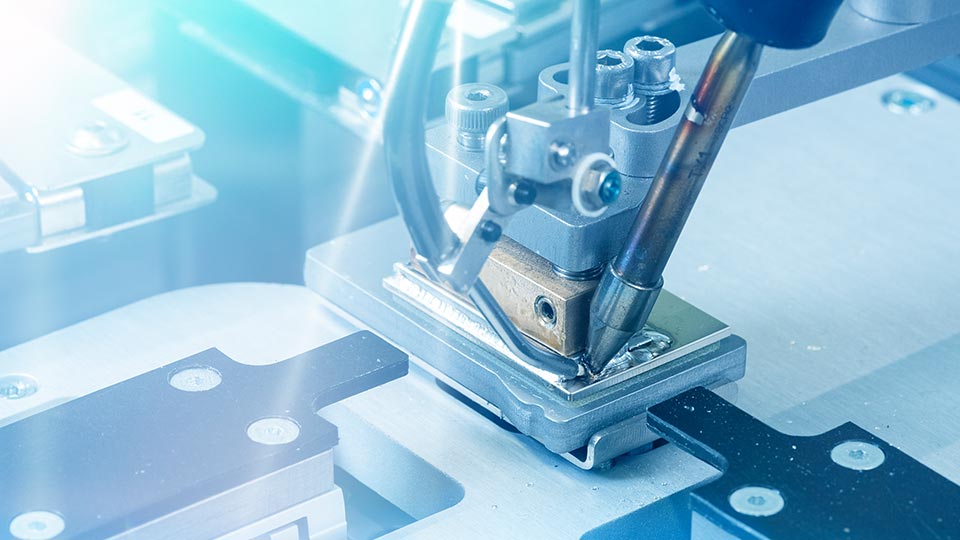

Bonding and joining systems

For gluing or dispensing, we can help you with semi-automated or fully automated robotic machines.

The all-rounders from Universal Robots are the ideal puzzle piece for a flexible application.

- Dispensing systems

- Buffer system

- Robot-based automatic gluing machines

Units for joining, pressing, riveting

We can also realise automatic feeding and thus fully automatic processing for pressing and riveting systems. The correct fit of the connections is checked using force-displacement measurement or VisionTec.

Get in touch with us

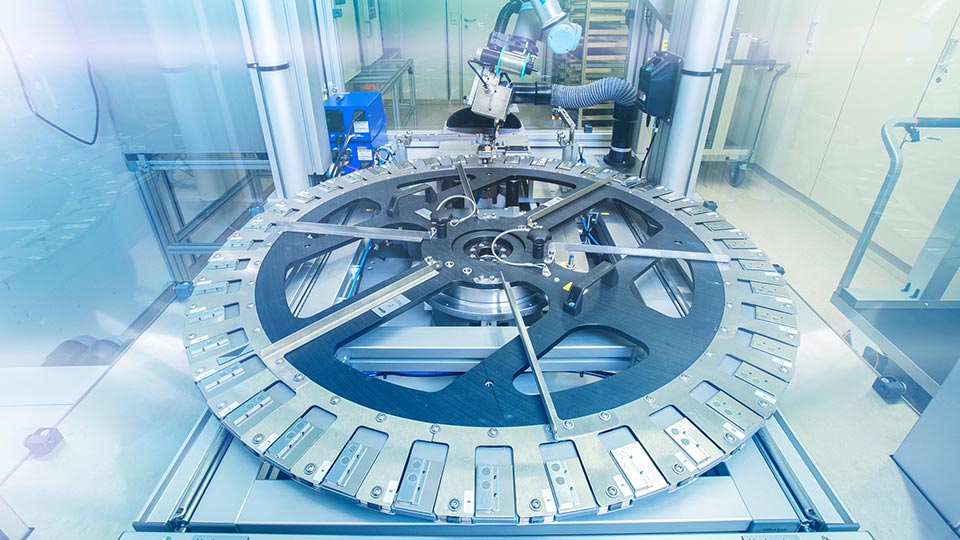

Feed and discharge conveyor technology

- Special conveyor belts

- Turntable solutions

Thanks to our fully automated solutions, we can offer a portfolio of customised conveyor belt and turntable technology solutions that leaves virtually nothing to be desired.

Get in touch with us